Our Mission

To create the ultimate UV cured filler paste to save time and money! We develop, manufacture and supply the highest quality products to consumers, businesses and resellers. As a proudly Australian company, we’re able to service our customers better by providing superior technical support and education.

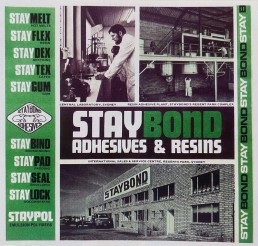

Company History

Founding Director Alan Anderson first established Monocure Pty Ltd in 1979 as an offshoot to his adhesives company called Staybond Pty Ltd after being bought by a Multinational. The business was created as an industrial chemical development and manufacturing company to supply UV cured inks to the traditional printing/packaging/label industries.

Fast forward nearly 40 years to 2016. Our Chief Development Chemist, Kevin Jarrett (a founding team member), created the first Australian-made resin for SLA/DLP/MSLA 3D printers. We saw that 3D Printing was an exciting and rapidly growing industry with a broad range of applications, and as a business, we committed ourselves to focus on this new challenge.

Alan’s son, Charlie, now runs Monocure 3D and is still a 100% family-owned and run business. Along with his team, Charlie is fully immersed (some might say obsessed!) in the world of 3D Printing, the technology, the creative possibilities and the community surrounding this dynamic industry.

The future is bright as Monocure 3D continues to be a market leader and at the forefront of this technology across the world.

Product Development

We understand what you need by actively engaging with the community through support chats, social media groups, surveys, and courses. This emersion in the community gives us a deep understanding of the needs and the issues of people globally and the confidence to develop products based on this understanding.

Our focus is on developing products to make your filling experience to be fast and efficient. Our team works around the clock developing products to help you succeed, including our own base resins, making our products unique and keeping pricing competitive.

Every new product goes through a stringent series of tests, including independent field testing before being launched. This level of testing ensures you only get products that work as described.

In-House Manufacturing

Keeping our manufacturing in-house makes communication faster and easier thanks to eliminating issues like language barriers and time-zone differences. In addition, keeping it in-house means you get the products you want when you need them. No shipping delays or stock run-outs when you’re in the middle of a project: we’ve got you covered!

With over 30 different product lines created and manufactured in-house, we sell to over 30 countries worldwide. Our facilities in beautiful Sydney, Australia, were designed and purpose-built for developing and manufacturing 3D products. If you are planning a trip here, please contact us for a tour of our facilities – we would love to show you around!

Quality Control

At Monocure 3D, we’re all about the result. We live by the motto “what you put in, is what you get out.”

We understand that a high level of detail, strength and durability are the properties that are important to you. So, we put our products through strict quality control following the ISO 9001 accreditation guidelines.

Every batch goes through a series of lab tests to compare the newest batch with the last; then, it is printed on standard 3D printers. By following this procedure, we can ensure batch-to-batch consistency of all our products, and you – our customers – get precisely the same product you ordered last time.

Distribution Partners

To help us offer you the best customer experience, we partner with the very best.

We’ve carefully selected shipping partners like DHL, Australia Post and Vanguard logistics (for sea freight) to ensure your parcel arrives on time, in excellent condition. With partners like these, and in conjunction with our growing list of Local Resellers, we have the whole world covered!

Speaking of Resellers – if you’re interested in joining our family and reselling our products, please fill out this application form, and we’ll come back to you as soon as possible.